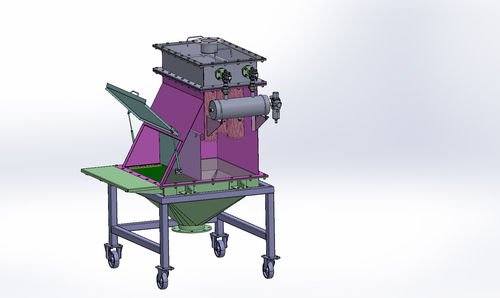

Dense Phase Vacuum Conveying System

600000 INR/Unit

Product Details:

- Product Type Dense Phase Vacuum Conveying System

- Color Silver

- Usage Industrial

- Material Stainless Steel

- Voltage 220 Volt (v)

- Warranty 1 Year

- Click to View more

X

Dense Phase Vacuum Conveying System Price

- 1 Unit

- 600000 INR/Unit

Dense Phase Vacuum Conveying System Specification

- 1 Year

- 220 Volt (v)

- Silver

- Stainless Steel

- Dense Phase Vacuum Conveying System

- Industrial

Dense Phase Vacuum Conveying System Trade Information

- 10 Unit Per Month

- 10 Days

Product Description

A Dense Phase Vacuum Conveying System is a sort of material taking care of system used to move mass materials starting with one area then onto the next utilizing a vacuum or negative tension. This system is especially appropriate for moving powders, granules, and other free-streaming materials. It is generally utilized in businesses, for example, food handling, drugs, synthetic compounds, and assembling. Key elements and benefits of Dense Phase Vacuum Conveying Systems include:

- Delicate Taking care of: These systems are fit for moving delicate or rough materials without causing harm.

- Decreased Air Utilization: Contrasted with weaken phase systems, dense phase systems for the most part require less air for conveying, making them more energy-effective.

- Limited Isolation: The dense phase activity limits the g amble of material isolation during transportation.

- Diminished Residue Discharges: The shut system configuration helps in controlling residue outflows and further developing by and large working environment security.

- Bunch and Persistent Modes: Dense phase vacuum conveying systems can be intended to deal with both group and consistent material transportation, offering adaptability in different modern cycles.

FAQs of Dense Phase Vacuum Conveying System:

Q: What is a Dense Phase Vacuum Conveying System?

A Dense Phase Vacuum Conveying System is a material taking care of system that utilizations negative strain or a vacuum to move mass materials, like powders and granules, through a shut pipeline or conduit in a dense, durable fitting.

Q: How does a Dense Phase Vacuum Conveying System work?

The system makes a vacuum at the material pickup point, which ensnares the material and structures a dense fitting. This fitting is then shipped through the conveying line, with controlled air infusion and delivery focuses to support material stream and forestall blockages.

Q: What enterprises regularly utilize Dense Phase Vacuum Conveying Systems?

These systems are utilized in businesses, for example, food handling, drugs, synthetics, plastics, and assembling, where delicate material taking care of, negligible isolation, and residue control are significant.

Q: What are the benefits of utilizing a Dense Phase Vacuum Conveying System?

Benefits incorporate delicate treatment of materials, diminished energy utilization, limited material isolation, controlled dust discharges, and reasonableness for both bunch and nonstop activities.

Enter Buying Requirement Details