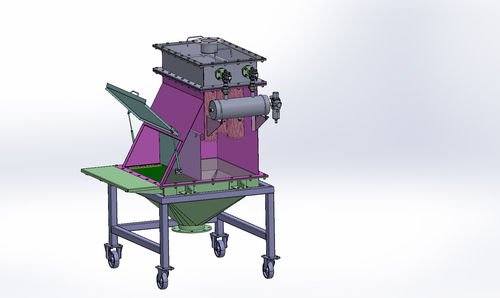

Jumbo Bag Unloading System

300000 INR/Unit

Product Details:

- Size Sizes Available

- Color Blue

- Product Type Jumbo Bag Unloading System

- Usage Industrial

- Material Mild Steel

- Voltage 220-440 Volt (v)

- Warranty 1 Year

- Click to View more

X

Jumbo Bag Unloading System Price

- 1 Unit

- 300000 INR/Unit

Jumbo Bag Unloading System Specification

- Sizes Available

- Blue

- 220-440 Volt (v)

- Jumbo Bag Unloading System

- Industrial

- 1 Year

- Mild Steel

Jumbo Bag Unloading System Trade Information

- 10 Unit Per Month

- 10 Days

Product Description

A Jumbo Bag Unloading System, otherwise called a Mass Bag Unloading System or FIBC (Adaptable Moderate Mass Holder) Unloading System, is a specific hardware arrangement intended for proficient and controlled unloading of huge bags or mass compartments loaded up with dry or semi-strong materials. These systems are generally utilized in businesses, for example, horticulture, synthetics, food handling, mining, development, and that's just the beginning, where taking care of mass materials in a protected and coordinated way is fundamental.

Here is an outline of the critical parts and highlights of a Jumbo Bag Unloading System:

- Bag Backing Construction: The system incorporates a strong edge or construction intended to hold the jumbo bag set up during unloading safely. This design frequently incorporates lifting components to deal with the heaviness of the bag.

- Crane or Forklift Connection: Jumbo bags are normally lifted and situated onto the bag support structure utilizing derricks, forklifts, or other lifting hardware.

- Bag Release System: When the bag is appropriately situated, a release instrument is utilized to exhaust the items in the bag. This system can incorporate elements, for example, bag massagers, stream helps, and vibration gadgets to guarantee smooth material stream.

- Dust Assortment System: Numerous systems integrate a residue assortment or regulation system to catch and control airborne residue particles produced during the unloading system, advancing a spotless and safe workplace.

- Material Transport: The system might incorporate conveying gear, like screw transports, pneumatic transports, or belt transports, to move the dumped material to downstream cycles or capacity.

FAQs of Jumbo Bag Unloading System:

Q: What is a Jumbo Bag Unloading System?

A Jumbo Bag Unloading System, otherwise called a Mass Bag Unloading System or FIBC Unloading System, is particular gear intended to proficiently and securely dump mass materials from enormous bags or compartments, frequently known as jumbo bags or FIBCs (Adaptable Middle of the road Mass Holders).

Q: Where are Jumbo Bag Unloading Systems utilized?

These systems are utilized in ventures, for example, farming, synthetic compounds, food handling, mining, and development, where mass materials should be dumped from huge bags or holders for additional handling or stockpiling.

Q: For what reason are Jumbo Bag Unloading Systems significant?

These systems guarantee controlled and proficient unloading of mass materials, advance administrator wellbeing, diminish dust discharges, and work with smooth material exchange to downstream cycles.

Q: What are the vital parts of a Jumbo Bag Unloading System?

Key parts incorporate a bag support construction, crane or forklift connection, bag release instrument, dust assortment system, material transport gear, ramble association, security elements, and control board.

Q: Will Jumbo Bag Unloading Systems handle various sorts of mass materials?

Indeed, these systems are intended to deal with an extensive variety of mass materials, including powders, granules, and other free-streaming materials.

Enter Buying Requirement Details