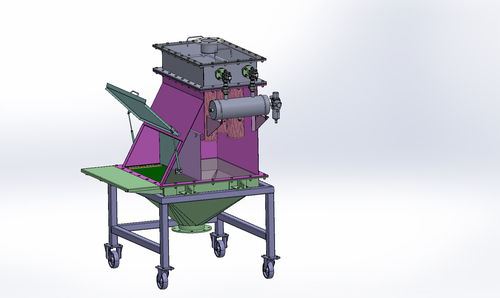

Pneumatic Powder Conveying System

Pneumatic Powder Conveying System Specification

- Usage

- Industrial

- Material

- Mild Steel

- Product Type

- Pneumatic Powder Conveying System

- Color

- Silver

- Voltage

- 220-440 Volt (v)

- Warranty

- 1 Year

Pneumatic Powder Conveying System Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 10 Days

- Main Export Market(s)

- Middle East, Asia, Western Europe, Africa

- Main Domestic Market

- All India

About Pneumatic Powder Conveying System

A Pneumatic Powder Conveying System is a particular sort of material taking care of system used to ship powdered or granular materials through a pipeline involving compacted air or gas as the conveying medium. This system is generally utilized in different businesses, including food handling, drugs, synthetics, plastics, and that's just the beginning, to effectively and securely move mass powders starting with one area then onto the next.

Benefits of Pneumatic Powder Conveying System:

- Sans dust Conveying: The encased system limits dust discharges during transportation.

- Adaptable Steering: Lines can be directed evenly, in an upward direction, or slantingly to fit space imperatives.

- Productive: Appropriate for significant distance conveying and various release focuses.

- Limited Material Debasement: Delicate conveying process diminishes material breakage.

FAQs of Pneumatic Powder Conveying System:

Q: What is a Pneumatic Powder Conveying System?

Q: How does a Pneumatic Powder Conveying System work?

Q: What sorts of materials can be shipped utilizing a Pneumatic Powder Conveying System?

Q: How would I pick the right Pneumatic Powder Conveying System for my necessities?

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pneumatic Conveying System Category

Pressure Conveying System

Price 500000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1 Year

Material : Mild Steel

Product Type : Pressure Conveying System

Usage : Industrial

Lean Phase Vacuum Conveying System

Price 500000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1 Year

Material : Mild Steel

Product Type : Lean Phase Vacuum Conveying System

Usage : Industrial

Jumbo Bag Unloading System

Price 300000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1 Year

Material : Mild Steel

Product Type : Jumbo Bag Unloading System

Usage : Industrial

Bag Dump Station System

Price 300000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1 Year

Material : Mild Steel

Product Type : Bag Dump Station System

Usage : Industrial