Showroom

Pneumatic conveying systems have a number of benefits, such as a decreased chance of cross-contamination, little product deterioration, and the capacity to transport items over great distances with little physical effort. Additionally, these systems may be modified to meet specific material and process needs.

In a variety of sectors, vacuum conveying systems provide an advanced and effective way of material movement that boosts output, lowers operating costs, and improves overall workplace safety. They are available in various arrangements.

Central Conveying Systems are generally utilized in enterprises like plastics fabricating, food handling, drugs, and that's just the beginning, where the exact and effective treatment of unrefined substances or completed items is basic for creation. These systems can differ in size and intricacy, contingent upon the particular necessities and size of the activity.

A Grain Conveying System is a particular kind of material dealing with system planned explicitly for the transportation of grains, like wheat, corn, rice, grain, oats, and other comparative farming items. These systems are generally utilized in grain storage spaces, flour plants, feed factories, and other horticultural and food handling activities to move grains productively and dependably.

Discover how our flexible screw conveyors may improve your workflow, increase efficiency, and help products move smoothly across your facility by looking through our assortment right now. Our conveyors are designed to provide dependable performance regardless of whether you are handling fine powders or tiny aggregates.

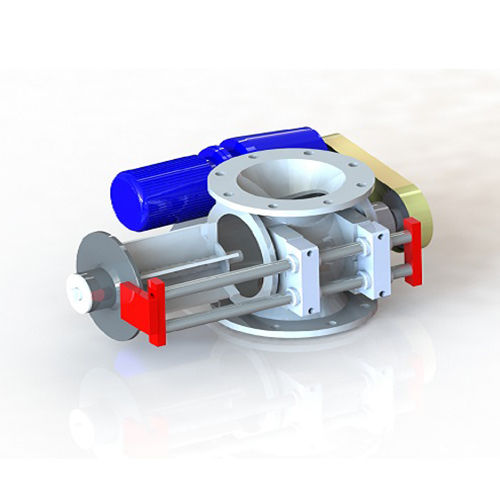

Diverter valves are crucial parts of many industrial systems that control the flow of gases or liquids. In order to provide effective and smooth transitions between various pipelines or process paths, these valves enable operators to regulate the direction of fluid flow inside a piping system.

Ribbon blenders provide a trustworthy method for producing homogeneous mixes that satisfy the requirements of contemporary production. These blenders have earned their reputation as essential tools, promoting efficiency and perfection in every mix, from producing bulk foods to meticulously crafting medicinal compositions.

Our airlock valves offer dependability you can rely on since they incorporate cutting-edge innovation and follow industry standards. Browse our portfolio to locate the ideal valve that will meet your unique operating requirements and help your industrial operations run smoothly.

Explore our extensive selection of Spice Making Machine that will help your culinary creations reach new heights. Our collection of equipment offers cutting-edge solutions for both skilled home cooks and professional chefs, from grinding and blending to powdering and combining.

We are engaged in manufacturing and supplying Centrifugal Fan. These fans are designed using premium quality raw materials in accordance with the industrial standards. These manufactured fans are engineered using advanced machinery in compliance with the international standards. Our offered range of plants is available in various sizes and colors as demanded by our clients and widely used for air as well as for pneumatic conveying. Known for its easy installation, robust construction and corrosion resistance, our range of Centrifugal Fan is available in single as well as double inlets and various capacities.

We are notable manufacturer and exporter of Air Classifying Mill that is appreciated for high tensile strength, smooth operation, easy handling, low running cost and longer service life. Manufactured at our state-of-the-art manufacturing unit utilizing high grade components as per the set industry norms, this mill is widely demanded in the market. The entire range of Air Classifying Mill is available in different specifications and can be customized to meet the varied needs of clients at leading market rates.

We are engaged in the manufacturing, supplying and exporting of Delumper Crusher. Owing to the less power consumption, these products are highly valued by the clients in the global market. These products are used to crush the small lumps of lighter duties into uniform coarser materials. The offered products are checked by our team of quality inspectors on various parameters to ensure zero damage. Our Delumper Crusher is delivered in a committed time frame at the clients end.

Clients can get from us an extensive gamut of Hammer Mill which is used for shredding different materials into fine particles in many industries. Machined using supreme quality raw materials, these Hammer Mills are praised by clients for features such as rugged construction, compact size, high operational fluency, no maintenance and longer working life.

With our immeasurable industry experience and familiarity, we have emerged as the principal manufacturer, exporter and supplier of a wide variety of Universal Mill. Offered machine is used for machining parts into precise sizes and shapes. Available in numerous specifications, this machine is efficiently manufactured under the supervision of our technical experts using superior quality components. Furthermore, this Universal Mill can be availed from us at nominal rates.

An Air Classifying Mill Plant, otherwise called an Air Classifier Mill Plant, is a particular modern handling office utilized for crushing and classifying powdered materials. It is usually utilized in different ventures, including drugs, synthetic substances, food handling, and minerals handling. The main role of an Air Classifying Mill Plant is to lessen the size of particles through crushing and to isolate or characterize particles in light of their size and different attributes.

A Grinding and Cleaning System is a modern interaction utilized for decreasing the size of materials through grinding and afterward cleaning or isolating the ground particles from debasements or undesired parts. This system is usually utilized in different ventures, including food handling, agribusiness, mining, and reusing. The essential targets of a grinding and cleaning system are to get ready materials for additional handling or to get an eventual outcome of a particular molecule size and tidiness.