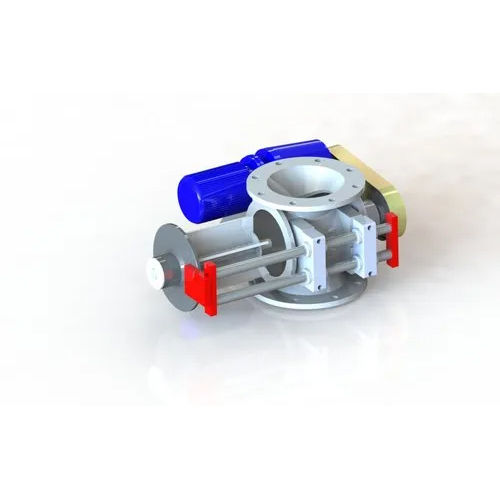

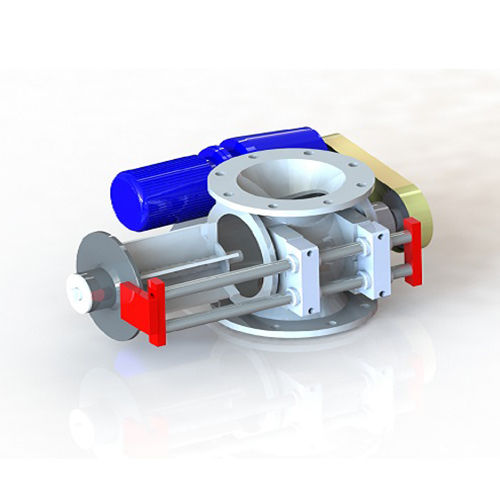

Rotary Airlock Valves

35000 INR/Unit

Product Details:

- Usage Industrial

- Product Type Rotary Airlock Valves

- Body Material Stainless Steel

- Color Gray

- Material Stainless Steel

- Power Hydraulic Watt (w)

- Pressure Medium Pressure PSI

- Click to View more

X

Rotary Airlock Valves Price And Quantity

- 1 Unit

- 35000 INR/Unit

Rotary Airlock Valves Product Specifications

- Medium Pressure PSI

- Gray

- Stainless Steel

- Industrial

- Stainless Steel

- Rotary Airlock Valves

- Hydraulic Watt (w)

Rotary Airlock Valves Trade Information

- 100 Unit Per Month

- 10 Days

Product Description

Rotary Airlock Valves, otherwise called rotary feeders or rotary valves, are fundamental parts in mass material dealing with frameworks. They are utilized to control the progression of materials between at least two frameworks, for example, between a container or storehouse and a conveying framework or between two segments of a pneumatic conveying line.

Benefits of Rotary Airlock Valves:

- Releasing materials from containers, receptacles, and storehouses.

- Taking care of materials into pneumatic conveying frameworks.

- Controlling the progression of mass solids in gravity-took care of frameworks.

- Segregating different tension zones in dust assortment frameworks.

FAQs of Rotary Airlock Valves:

Q: What is a Rotary Airlock Valve?

A: A Rotary Airlock Valve is a mechanical gadget used to control the progression of mass materials while keeping an impermeable seal between various strain zones. It comprises of a pivoting rotor with vanes or edges that move material from one side of the valve to the next.

Q: How does a Rotary Airlock Valve function?

A: The rotary valves rotor turns inside a lodging, making pockets or cells that catch material from the bay side and release it to the power source side. As the rotor turns, it keeps air or gas from streaming once again into the delta, keeping up with pressure differentials and forestalling material spillage.

Q: What are the vital parts of a Rotary Airlock Valve?

A: The fundamental parts of a Rotary Airlock Valve incorporate the lodging, rotor with vanes or sharp edges, drive instrument (engine or stuff), and seals. A few rotary valves likewise include extra parts like customizable tips on the rotor vanes for further developed fixing.

Q: What kinds of materials can be taken care of by Rotary Airlock Valves?

A: Rotary Airlock Valves can deal with an extensive variety of mass materials, including powders, granules, pellets, chips, pieces, from there, the sky is the limit. The decision of valve plan and material of development relies upon the attributes of the material being dealt with.

Q: Are there various kinds of Rotary Airlock Valve plans?

A: Indeed, there are different kinds of Rotary Airlock Valve plans, including drop-through, blow-through, and side-section setups. The decision of configuration relies upon elements, for example, material properties, stream rate, and framework necessities.

Q: How would I pick the right Rotary Airlock Valve for my application?

A: Consider factors, for example, the kind of material, molecule size, stream rate, pressure differentials, and space requirements. Talking with makers or specialists can assist you with choosing the proper valve for your particular application.

FAQs of Rotary Airlock Valves:

Q: What is the body material of Rotary Airlock Valves?

A: The body material of Rotary Airlock Valves is Stainless Steel.Q: What is the color of Rotary Airlock Valves?

A: The color of Rotary Airlock Valves is Gray.Q: What is the usage of Rotary Airlock Valves?

A: The usage of Rotary Airlock Valves is Industrial.Q: What is the material of Rotary Airlock Valves?

A: The material of Rotary Airlock Valves is Stainless Steel.Q: What is the pressure range of Rotary Airlock Valves?

A: The pressure range of Rotary Airlock Valves is Medium Pressure PSI.Enter Buying Requirement Details