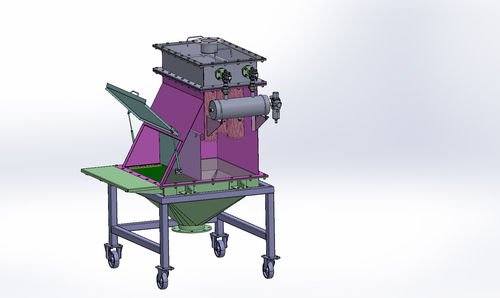

Weighing and Batching System

800000 INR/Unit

Product Details:

- Color Silver

- Usage Industrial

- Size Sizes Available

- Product Type Weighing and Batching System

- Material Mild Steel

- Voltage 220-440 Volt (v)

- Warranty 1 Year

- Click to View more

X

Weighing and Batching System Price

- 800000 INR/Unit

- 1 Unit

Weighing and Batching System Specification

- 220-440 Volt (v)

- 1 Year

- Silver

- Mild Steel

- Sizes Available

- Weighing and Batching System

- Industrial

Weighing and Batching System Trade Information

- 10 Unit Per Month

- 10 Days

Product Description

A Weighing and Batching System is a particular arrangement utilized in modern cycles to precisely gauge and control the amount of materials that are being administered or added to an interaction. This system is vital in different enterprises, for example, food handling, drugs, synthetic compounds, horticulture, and assembling, where exact estimations and precise batching are fundamental for item quality, consistency, and administrative consistence.

Here are the critical parts and highlights of a Weighing and Batching System:

- Weighing Hardware: This incorporates load cells, scales, or weighing stages that precisely measure the heaviness of materials. Load cells are sensors that convert the power of the load into an electrical sign, which is then used to decide the material's mass.

- Containers or Canisters: Containers or receptacles are compartments that hold the materials to be gauged and grouped. These holders are in many cases put on the weighing hardware and can be furnished with gadgets, for example, slide doors or valves for controlled material release.

- Batching Controls: Batching controls are ordinarily a piece of a computerized system that deals with the exact weighing and administering of materials. These controls can be programmable rationale regulators (PLCs) or PC based systems that screen and manage the cycle.

- Transports and Feeders: These parts are utilized to ship materials to and from the containers or receptacles. They guarantee a steady and controlled progression of materials into the weighing system.

- Batching Programming: Batching programming permits administrators to include explicit recipes, target loads, and different boundaries. The product guarantees that the right amounts of materials are gauged and administered by the ideal recipe.

FAQs of Weighing and Batching System:

Q: What is a Weighing and Batching System?

A Weighing and Batching System is a particular arrangement utilized in modern cycles to precisely quantify and control the amount of materials that are being administered or added to a cycle. It guarantees exact and steady batching for different ventures.

Q: Where are Weighing and Batching Systems utilized?

These systems are utilized in ventures, for example, food handling, drugs, synthetic compounds, agribusiness, and assembling, where exact estimation and control of materials are fundamental for quality, consistency, and consistence.

Q: Why are Weighing and Batching Systems significant?

Weighing and Batching Systems guarantee item quality, limit material waste, upgrade process productivity, and work with consistence with administrative standards.

Q: What are the vital parts of a Weighing and Batching System?

Key parts incorporate weighing gear (load cells or scales), containers or receptacles, batching controls (PLCs or programming), transports or feeders, batching programming, dust assortment systems (if necessary), material handling instruments, and information logging abilities.

Q: How does the weighing system function in a Weighing and Batching System?

The system utilizes load cells or scales to quantify the heaviness of materials in containers or receptacles. The weight is changed over into an electrical sign, which is then used to control the apportioning of materials.

Enter Buying Requirement Details